How We Helped a Garment Factory Solve Packaging Challenges with Custom PVC Bags

In central Taiwan, a garment factory specializing in high-end women's fashion came to us with a pressing issue. Their carefully tailored pieces were being damaged during shipping—creased, scuffed, or poorly presented upon arrival. Traditional packaging like paper and standard plastic bags simply couldn't provide the protection or presentation their products demanded. Worse yet, poor packaging diminished the perceived value of their brand.

Our collaboration began with one question:

How can we design a packaging solution that protects during transit, presents beautifully on shelves, and lasts longer for reuse?

The Challenge: Fragile Packaging Meets Premium Fashion

This garment manufacturer serves markets across Japan, Europe, and the U.S. Their designs are refined and minimal, requiring packaging that mirrors the same level of attention to detail. However, long-haul shipping often left garments crumpled or poorly displayed.

Their team was looking for a packaging solution that would:

Protect during international logistics

Enhance brand presence in retail

Be sustainable, or at least reusable

Fit a variety of apparel sizes without the cost of too many SKUs

Our Solution: A Smarter, Longer-Lasting PVC Bag

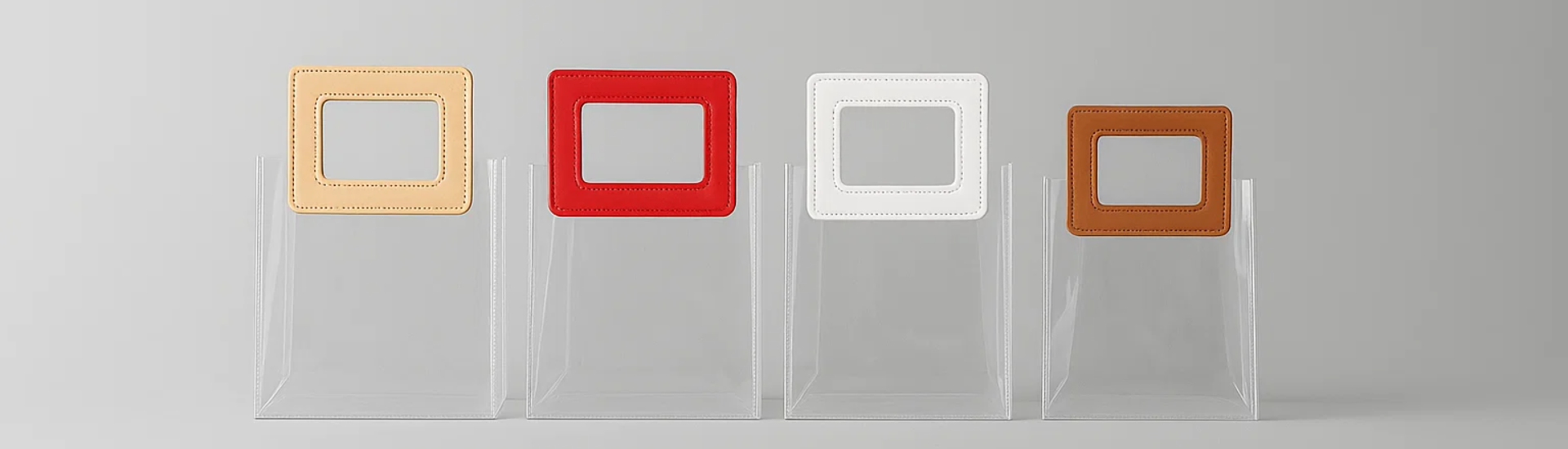

We designed a custom semi-frosted PVC zipper bag featuring:

Frosted body with high clarity front – protecting contents while still showing the product

Smooth zipper closure – allows customers or store staff to reseal the bag without damage

Reinforced seams – improved durability during stacking and shipment

Euro punch hole – optimized for in-store hanging display

What sets this packaging apart is the choice of material. We used a UV-resistant, anti-yellowing PVC formula, extending its shelf life both during and after logistics. Even under sunlight or humidity, the bag resists cracking, becoming brittle, or discoloring.

The Result: Better Logistics and a Better Customer Experience

The first production run was used for a seasonal collection launch. Within weeks, the client received encouraging feedback from a Japanese distributor:

“The garments arrived beautifully packed—no wrinkles, no scratches, just a clean and professional presentation. We loved that customers could also reuse the bags for storage.”

The factory also reported that returns related to damaged packaging dropped significantly. In addition, some retailers began treating the packaging as a bonus gift, adding unexpected value to their end customer's experience.

Extending Product Life: From Packaging to Reusable Asset

This project wasn't just about making a stronger bag—it was about rethinking packaging as an experience and a sustainable touchpoint.

Here’s how we helped extend the life cycle of a typical PVC bag:

Used higher-grade PVC to resist UV, heat, and oxidation

Designed closures for reusability

Made sizes flexible and multi-purpose for internal storage reuse

Enabled brand-level printing to replace secondary packaging or labels

As a result, the factory was able to cut down on repackaging costs, and their end users began repurposing the packaging, turning it into a long-lasting touchpoint between brand and consumer.

Conclusion: From One Project to Long-Term Value Creation

The lifespan of a PVC packaging bag isn't just about how long it lasts physically—it's about how well it serves its purpose, supports your brand, and fits into a more responsible supply chain.

Our collaboration with this garment factory showed us that better packaging leads to better logistics, better retail performance, and better customer experience.

If your business is facing similar challenges—whether it’s damaged packaging, uninspiring retail presentation, or one-time-use waste—we’re ready to help you design a smarter, longer-lasting packaging solution that works.

Let's build something better together.

繁体中文

繁体中文