From Selling Bags on Platforms to Building Our Own PVC Packaging Website:

A Transformation Triggered by Thickness

A few years ago, we were selling all kinds of PVC packaging bags on Amazon and Alibaba.

Back then, we believed that as long as the product was high quality, reasonably priced, and reliably delivered, we could meet every customer's needs.

But we soon discovered—it wasn't that simple.

Act 1: The Limitations of Platforms

On Amazon FBA, we had to send our goods to overseas warehouses in advance, with fixed sizes, weights, and specifications.

That meant—the thickness of the bags couldn't be changed at will.

Yet in the packaging world, thickness is a critical parameter:

A bag with 0.3 mm thickness and one with 0.4 mm can have drastically different resistance to cracking in cold-chain transportation.

Slightly reducing thickness can lower shipping costs; slightly increasing it can improve protection—but also raise DIM (dimensional weight) shipping charges.

If the formula is wrong, even thicker bags can become brittle in low temperatures; if the formula is right, a thinner bag can perform just as well.

But in Amazon's system, these crucial data points didn't exist.

A customer would only see one line: “PVC Bag, Size: 20x25 cm”—without thickness, formula, or sealing strength, let alone how those factors affect product safety or freight costs.

On Alibaba, customization was possible, but the instant chat model made it hard to conduct structured needs analysis.

A custom order requiring discussion of formula, cold-resistance testing, print resolution, and shipping solutions often got chopped into fragmented conversations, scattered across different times and people.

Act 2: The Time We Had to Say “No”

I remember one time, a European food e-commerce seller came to us.

His products were shipped via cross-border cold chain, and due to insufficient bag thickness, the breakage rate was alarmingly high.

He was straightforward: “I'm willing to pay for thicker bags—at least make sure they arrive to customers intact.”

The problem? He had found us through Amazon.

Under Amazon’s system, we couldn’t change thickness for him alone—doing so would create a new SKU, requiring a complete re-entry into the warehouse and supply chain.

We knew exactly how to solve his problem, but in that context, we could only say: “Sorry, we can't do that.”

That was the moment I realized:

Platforms excel at selling standardized products, but our customers needed packaging solutions that could be fine-tuned—or even redesigned—for real-world scenarios.

And the platform couldn't present that, nor would it allow us to.

Act 3: Leaving the Platforms, Redefining Service

After many similar experiences, we made a difficult decision—to exit all e-commerce platforms.

We realized that staying on these platforms meant we couldn’t truly help customers solve problems, couldn't fully meet their needs, and couldn't maintain our own product and service standards.

Rather than passively adapting to platform rules at the expense of our expertise and values, we chose to leave—and build a space that truly reflects our philosophy.

Act 4: Building Our Own Space

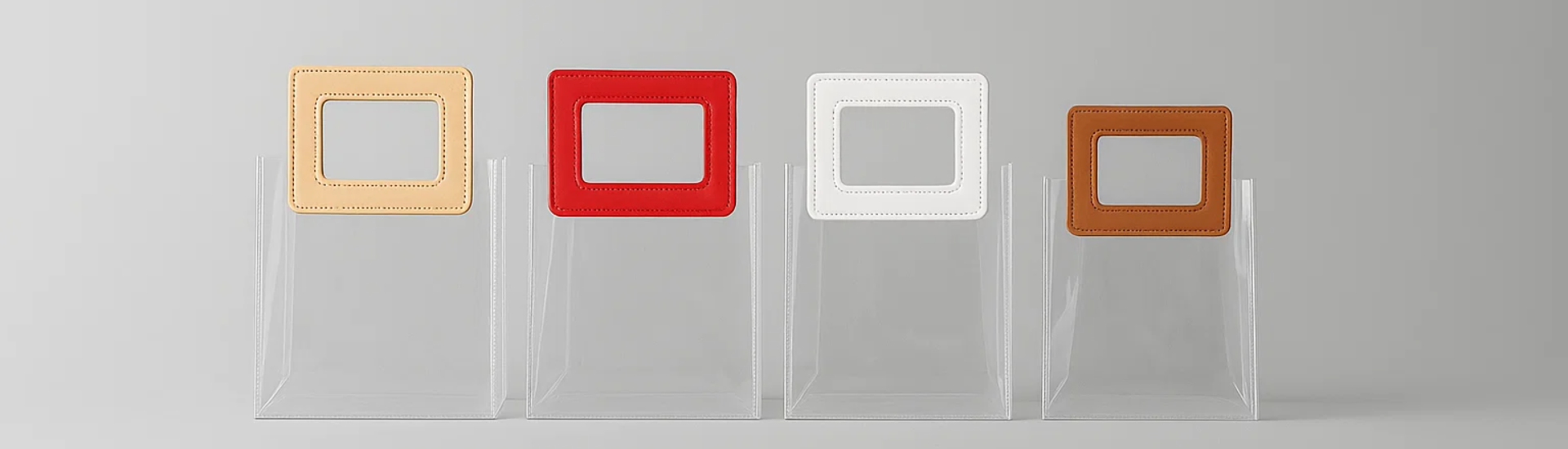

That's why we created the PVC Package official website.

It's not there to list a bunch of SKUs—it's there to showcase every detail of a packaging solution:

thickness, formula, sealing method, hang hole placement, printing process, testing standards, and how each of these impacts shipping safety, cost control, and brand image.

On our website, customers can:

Fill out a requirements form with transportation temperature ranges, product weight, and display methods.

Choose thickness and instantly see how it affects freight and protection levels.

Learn the differences between formulas in terms of cold resistance, anti-yellowing, and flexibility.

Receive recommendations based on TCO (Total Cost of Ownership), not just unit price.

Act 5: Making Thickness a Visible Value

Since launching our website, we no longer have to hide thickness—an important parameter—behind the product listing.

Instead, we put it front and center, helping customers understand:

Why in cold-chain shipping, an extra 0.05 mm—going from 0.3 mm to 0.35 mm—can reduce breakage rates from 8% to 1%.

Why in local retail scenarios, a 0.2 mm lightweight bag can lower logistics costs while keeping display quality high.

Why the formula matters more than thickness—because the wrong formula won’t solve the problem, even with added thickness.

Thickness is no longer just a number—it's part of the design solution, connected to cost, durability, and the customer experience.

Epilogue: Why We Left the Platforms

Many people ask us: “You were doing well on Amazon and Alibaba—why did you leave?”

We've asked ourselves the same question.

Leaving meant giving up steady traffic and a familiar sales channel.

But time and again, we faced the same situation:

A customer came to us with a real pain point, looking for a packaging solution that worked.

We knew the answer—but because of platform rules, we couldn't give them the version they truly needed.

We ended up selling a product we ourselves didn't think was “good enough.”

For us, that wasn't just a business regret—it was a conflict of values.

We didn't start this company to be a “standard product distributor.”

We started it to be a packaging consultant who could solve real problems.

When the platform model prevented us from showing crucial product details (like thickness, formula, or structural design),

when we had to sacrifice protective performance to fit warehouse and delivery limitations,

when we knew there was a better solution but couldn't implement it—

we had to ask ourselves: If we stay here, are we still true to our mission?

The answer was no.

We didn't want to be the supplier who says “Sorry, we can't.”

We wanted to be the partner who says “No problem, I have a solution.”

So we made the decision to leave all e-commerce platforms,

and to build a space fully under our control—

where we can openly discuss how thickness impacts shipping costs,

where we can choose the best formula for cold environments,

where we can adjust bag design based on product characteristics,

and where we can create a dedicated packaging profile for each customer.

We know this path will be slower and harder, but it's truly ours.

Because only this way can we deliver the quality and service we promise—without compromise.

繁体中文

繁体中文