Cutting Energy Costs with PVC Strip Curtains: How a Japanese Meat Processor Solved Their Cold Storage Problem

PVC strip curtains have long been valued for their ability to improve operational efficiency in industrial and commercial environments. When used correctly, they offer a range of benefits:

Partitions – Separate different rooms while maintaining temperature between them.

Barriers – Keep dust, insects, or airborne particles away from sensitive machinery.

Noise Reduction – Reduce the impact of heavy machinery noise, making nearby areas more comfortable.

Temperature Control – Maintain stable indoor temperatures to cut down on energy consumption.

These benefits are well-known on paper—but they become truly compelling when put to the test in real-world conditions.

The Challenge: High Electricity Costs in Japan's Cold Storage

In Japan, electricity rates are among the highest in the world. For one meat processing plant we worked with, their cold storage units were a constant source of frustration.

Despite taking multiple energy-saving measures, their cold rooms still consumed more electricity than they had budgeted for.

Every kilowatt mattered, and the company was under pressure to reduce their operational costs without compromising food safety or production efficiency.

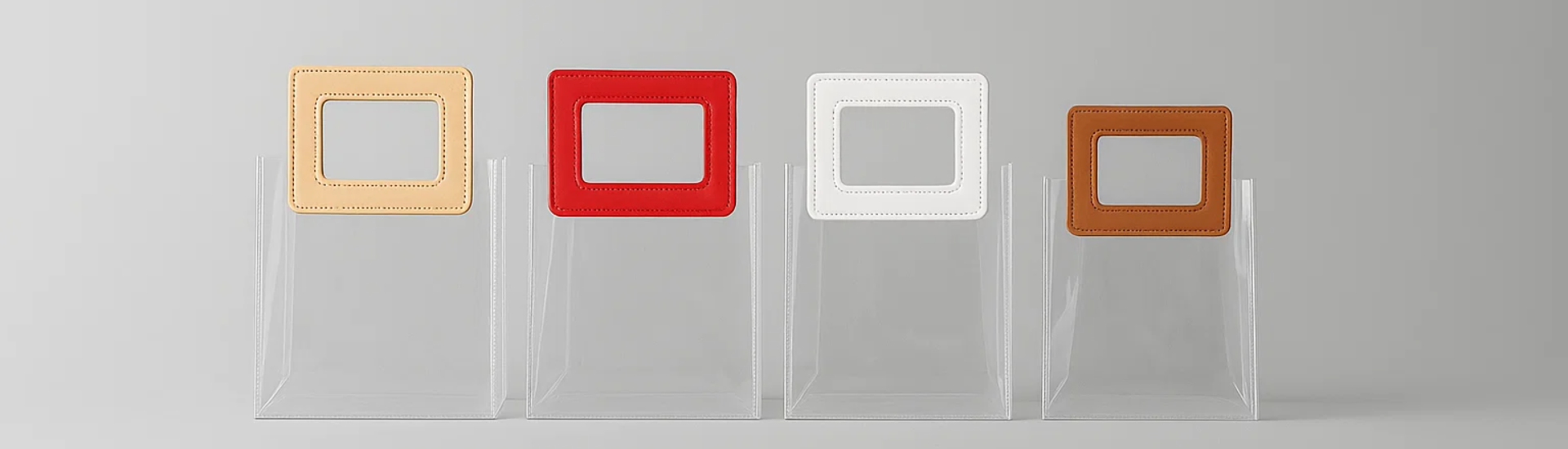

Our Solution: Low-Temperature PVC Roll Material with the Right Thickness

After carefully reviewing their cold storage layout and operating conditions, we proposed installing low-temperature grade PVC strip curtains made from our specialized roll material.

The choice of thickness was critical:

Too thin, and the strips wouldn't effectively block cold air from escaping.

Too thick, and the strips would be unnecessarily heavy, harder for staff to pass through, and more expensive—both in material cost and in wear on the mounting hardware.

We recommended an optimized thickness that balanced durability, ease of use, and maximum thermal retention.

The Results: Measurable Energy Savings and a Happier Operations Team

Once the new strip curtains were installed, the plant’s cold storage units immediately showed improved temperature stability.

The frequency of compressor cycles dropped, and energy usage reports in the following months confirmed a significant reduction in electricity consumption.

Even better, staff could move in and out of the cold rooms without major obstruction—keeping workflow smooth while still retaining cold air.

The plant manager told us:

“We didn't realize that the right material grade and thickness could make this much of a difference. It's not just about having strip curtains—it's about having the right strip curtains.”

Takeaway: Details Matter

PVC strip curtains can be a cost-effective way to save energy, improve workplace comfort, and protect equipment—but their real performance depends on material selection, thickness, and installation quality.

For the Japanese meat processor, a tailored low-temperature PVC solution turned an ongoing cost problem into a long-term operational advantage.

繁体中文

繁体中文