Beating the Cold: How We Helped a Korean Wig Brand Upgrade to PVC Packaging That Protects and Saves Costs

In the global flow of goods, PVC packaging has long been a popular choice for retail and e-commerce thanks to its excellent transparency, snug fit, and dust- and tamper-resistant properties. It can tightly wrap products of various shapes, enhance shelf presentation, and conveniently bundle multiple items together for customer ease.

However, even the most reliable materials can face challenges in extreme conditions—especially in severe cold, where PVC's durability is often put to the test.

The Problem: Cracks and Losses in Low Temperatures

Our client, a Korean wig brand, sells primarily to the U.S. While most regions are temperate, certain areas—such as Las Vegas in winter—can see sharp temperature drops to near or below freezing at night.

Their original packaging, supplied by another manufacturer, performed well in normal conditions. But in low temperatures, PVC became brittle and prone to cracking during transport. This not only compromised the product's appearance but also increased return rates, after-sales costs, and, ultimately, damaged brand perception.

The Misconception: Thickness Alone Doesn't Solve It

Before working with us, the brand had tried a common fix—increasing the packaging thickness. While this offered some delay in brittleness, it did not fundamentally address PVC's loss of flexibility in cold weather.

Worse still, thicker packaging meant heavier shipments, which translated into higher transportation costs. For high-volume, long-distance shipments, this extra expense was far from negligible.

Our Solution: Cold-Resistant Material Upgrade

After a thorough review of their logistics routes, storage conditions, and market climate, we developed a low-temperature-resistant PVC packaging solution:

Special PVC formulation that retains flexibility and resists cracking at temperatures down to -15°C to -20°C;

Optimized material structure and shrink ratio to prevent over-tightening and product deformation during long-term storage;

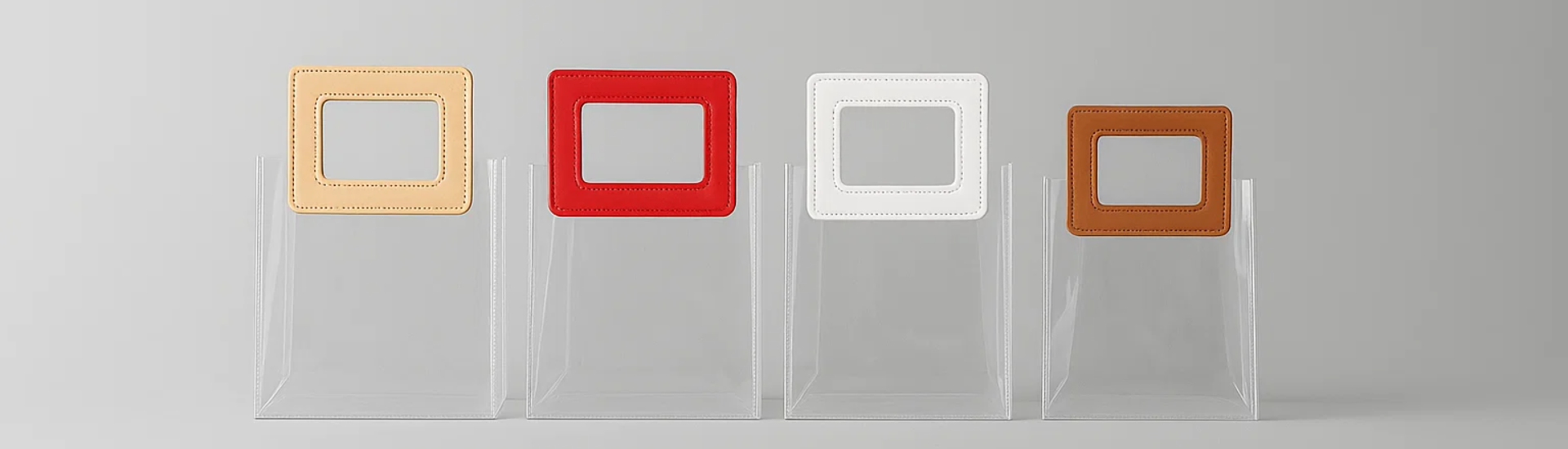

Maintained high transparency and gloss to showcase wigs attractively in retail settings;

Enhanced tensile and abrasion resistance without unnecessary thickness increases—protecting the product while keeping shipping costs under control.

The Results: Less Damage, Better Experience

Once the new packaging was introduced, winter transport damage rates in the U.S. dropped dramatically, and returns decreased significantly. Products arrived at retail stores and in customers' hands in perfect condition.

Beyond protection, the upgraded PVC packaging improved shelf appeal with its clarity and smooth finish, elevating the perceived value of the wigs. The brand confirmed that the new packaging was no longer just a shipping necessity—it became an integral part of the customer experience.

Conclusion

This case proves that the key to solving packaging challenges is not more material, but the right material and design.

By precisely tailoring PVC performance to withstand specific environments, we helped the Korean wig brand maintain product quality through harsh winters while controlling transportation costs—achieving the perfect balance between protection and economy.

And just like in this case, our mission remains clear: to deliver packaging solutions that truly fit our clients’ markets, products, and customer expectations.

繁体中文

繁体中文